product introduction

Steel box beam, also called steel box girder, is a commonly used structural form for long-span bridges. Generally used on large-span bridges, it is called steel box girder because it looks like a box.It can be divided into three types: single box girder bridge, double box girder bridge, and multiple box girder bridge.

In large-span cable-supported bridges, the steel box main girder spans several hundred meters or even thousands of meters.

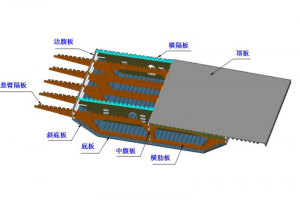

It is divided into several beam sections for manufacturing and installation, and its cross section has the characteristics of wide and flat shape, and the aspect ratio reaches about 1:10. Steel box girder is generally formed by fully welding the top plate, bottom plate, web, and transverse partitions, longitudinal partitions and stiffeners. The top plate is an orthotropic bridge deck composed of a cover plate and longitudinal stiffeners. The thickness of each plate of a typical steel box girder can be: cover thickness 14mm, longitudinal U-shaped rib thickness 6mm, upper mouth width 320mm, lower mouth width 170mm, height 260mm, spacing 620mm; bottom plate thickness 10mm, longitudinal U-shaped stiffeners ; The thickness of the inclined web is 14mm, the thickness of the middle web is 9mm; the spacing of the transverse partitions is 4.0m, and the thickness is 12mm; the beam height is 2~3.5m.

Steel box girder is a structural form often used in engineering. In order to study the influence of the spacing of the transverse diaphragms on the distortion of the simply supported steel box girder under concentrated load, the simple support steel box girder with different numbers of transverse diaphragms was set to compare its Distortion effect and rigid torsion effect under load, the change curve of maximum distortion effect with the number of diaphragms is obtained. Concentrated load is applied to the top of the box girder web, and it is adopted according to the four working conditions of distortion, rigid torsion, symmetrical bending and eccentric load. The method of load decomposition is calculated.

Zhenjiang Great Wall Heavy industry has more than 50 tons of cranes, professional design, welding, and installation teams undertake the production and installation of various steel box beams.

Product applications

Because of its structural form, steel box girder is generally used for municipal elevated and ramp steel box girder; construction period traffic organization long-span cable-stayed bridge, suspension bridge, arch bridge stiffening girder and pedestrian bridge steel box girder.

Product advantages

1. High tensile strength and high bearing capacity

2. Light structure, suitable for long-span bridges

3. Easy installation, low cost, short cycle

4. Guaranteed quality and quantity, and high reliability

5. High construction efficiency and high safety